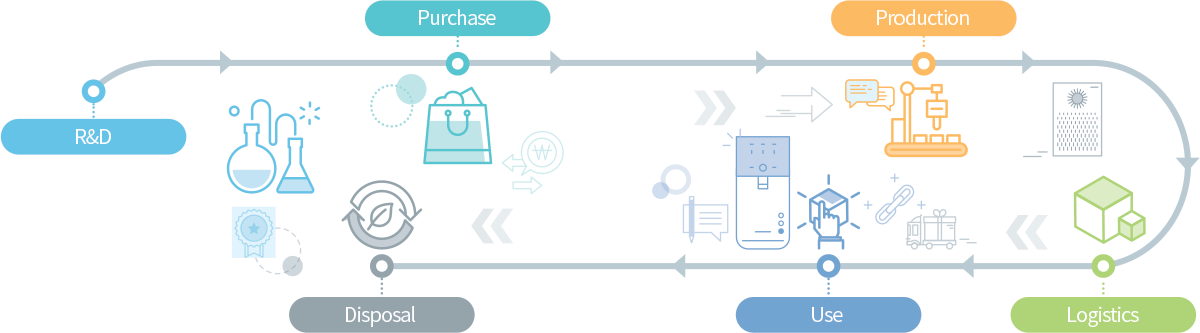

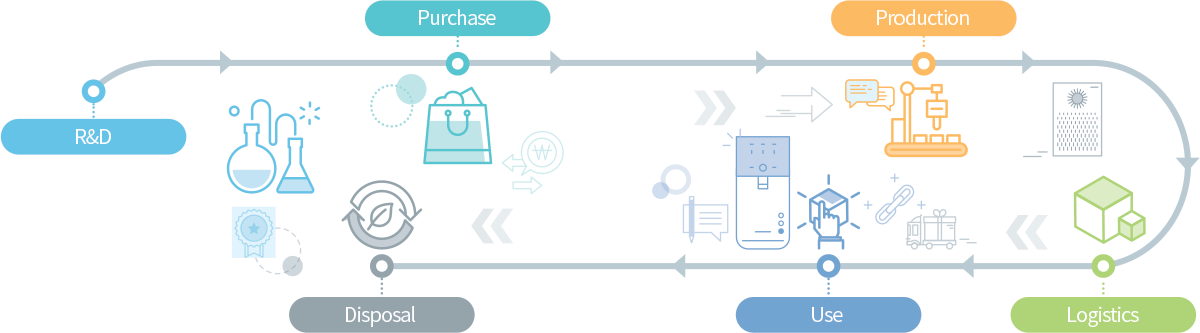

Woongjin Coway prioritizes safety and environment in the overall value chain from the R&D stages to the use and waste of the product by the customer so that customers can have a safer product experience.

R&D

R&D-

Certification/Regulation management

Enhancement of safety design standards

Review and verification(assessment) for products/parts

Acquisition of products/parts certification

Evaluation of certification conformity

-

Reviewing the environmental safety of materials/parts, chemical substances, products and packaging

- Establishing the chemical substances control system and continuous inspection of materials and parts

- Analyze hazardous materials and inspect the safety of material substances

Product environmental safety assessment

- Analyze hazardous substances and adequacy of product chemicals

Packaging environmental safety assessment

- Analyze chemicals and regulations(resource recycling method, etc.) and review gradual introduction of paper cushion

-

- Operation of International Accredited Laboratory and Integrated Certification System

Purchase

Purchase-

Select and maintain suppliers/parts that suit environmental safety

- Shared growth through supplier training for development

- Include environmental safety compliance items in contract

- Manage/support supply network for environmental safety

- Regular visits to suppliers and improvement

-

Assessment of selected parts and packaging

- Materials/Parts: Hazardous/Chemical substance inspection

- Packaging: Appearance, measurement, hazardous/chemical substance inspection

- Supplier assessment and company visits

Production

Production-

Stock inspection and management of environmental safety in products

- Sampling compliance with the level of hazardous substances in mass-produced parts

- Checking the adequacy for environmental safety among parts

-

Real-time safety verification and plant review management

- Sampling in compliance with the level of hazardous substances in mass-produced products and checking the environmental safety adequacy of products

- Monitoring/Improving any potential change in certification effectiveness during production

- Reviewing and managing whether the production system meeting certification/regulations is maintained

-

OEM and ODM

- Sampling for compliance with the level of hazardous substances in mass-produced products

- Checking the environmental safety adequacy of products

- Conducting regular education/inspections for manufacturers and making improvements

Logistics

Logistics-

- Reducing packaging such as package vinyl, etc.

- Applying eco-friendly packaging(GP mark)

- Separating and transferring service waste(recycling/disposal)

Use

Use-

Follow-up Certification Management

- Monitoring whether the effectiveness of acquired certification is maintained/Making improvements

-

Reinforcing hygiene/security through technology innovation

- Designing the standard module to allow easy exchange of parts and stained areas

- Developing new materials with enhanced safety

- Developing smart signaling service technology

-

Guide eco-friendly use and recollection

- Re-collect filters and consumable material

- Maintain highest energy efficiency rating

Disposal

Disposal-

- Establishing/Operating the reverse logistics process

- Zero incineration and reclamation(using solidified fuel)

- Using easily recyclable materials and applying structure design for easy product disassembly

- Implementing circular economy and producing/selling refurbished products

R&D

R&D Purchase

Purchase Production

Production Logistics

Logistics Use

Use Disposal

Disposal